ELSA Project

Project Details

Description

In the ever-evolving semiconductor and electronics industry, the demand for high-purity chemicals remains paramount. MYCON, a prominent player in the construction industry, embarked on a groundbreaking project in Plainview, Texas, partnering with Marubeni Protechs Manufacturing to construct an electronic-grade sulfuric acid (ELSA) plant.

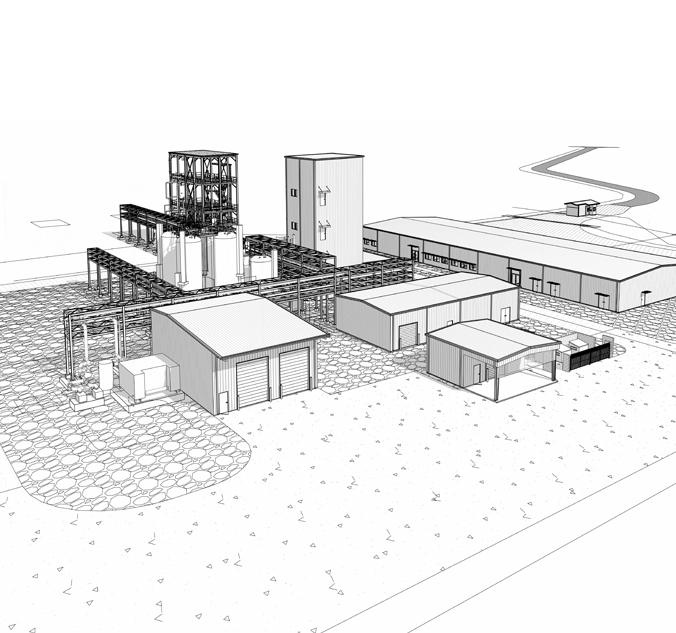

Electronic-grade sulfuric acid is a vital high-purity chemical used extensively in the semiconductor and electronic manufacturing processes. The primary objective of this project is to meet the escalating global demand for ELSA and ensure a stable supply to semiconductor and electronic manufacturing facilities worldwide. The ELSA plant encompasses a range of structures and buildings designed to facilitate the production and distribution of electronic-grade sulfuric acid. The facility features:

- Pre-Engineered Metal Buildings: The project comprises five pre-engineered metal buildings, totaling 21,910 SF. These structures are tailored to accommodate the various stages of ELSA production, ensuring efficiency and safety.

- Prefabricated Guard Shack: To maintain strict security protocols, a prefabricated guard shack is strategically positioned to oversee access to the facility.

- Office Building with Clean Room: An office building, equipped with a clean room, serves as the nerve center for administrative and operational activities.

- Warehouse and Shipping Building: This building is dedicated to storage and logistics, streamlining the packaging and distribution of ELSA.

- Truck Scale: Ensuring precision in material handling and shipping, a truck scale is integrated into the facility’s infrastructure.

- Utility Building: A dedicated utility building houses essential systems and equipment, guaranteeing the uninterrupted production of electronic-grade sulfuric acid.

- Covered Sulfur Trioxide (SO3) Structure: This structure is designed to safely house and manage sulfur trioxide, a critical component in ELSA production.

- ELSA Module: The heart of the facility, the ELSA Module, is where the electronic-grade sulfuric acid is produced, meeting the stringent quality standards required by the electronics industry.

- Towers and Process Piping: The facility features towers with connected process piping, facilitating the efficient flow of materials throughout the production process.

Construction of the ELSA manufacturing facility commenced with groundbreaking, and the project is scheduled for completion in May 2024. With the establishment of this facility, the supply chain for electronic-grade sulfuric acid will become more dependable, reducing potential disruptions in semiconductor and electronics manufacturing. The facility’s strategic location in Texas positions it to serve key semiconductor and electronic manufacturing facilities worldwide, contributing to the growth of the global electronics industry.

Conclusion

MYCON’s collaboration with Marubeni Protechs Manufacturing to construct the ELSA manufacturing facility in Plainview, Texas, represents a pivotal moment in the electronics industry. The project’s successful completion in May 2024 will not only meet the rising demand for electronic-grade sulfuric acid but also contribute significantly to the reliability and quality of electronic manufacturing processes on a global scale.